Why it matters: Many enthusiasts continue to keep floppies and the data they contain alive. However, their fragility poses an obstacle – dust, fingerprints, and scratches can all be formidable enemies when it comes to preserving those digital memories. But one clever British retro-computing enthusiast has come up with a wonderfully bizarre solution for resurrecting your crusty old floppies.

Rob Smith unveiled his automatic floppy disk cleaning contraption earlier this year at the Amiga Kickstart event in Nottingham, where he says it "put a smile on just about everyone's face." This thing is wild – it's basically like a miniaturized automatic car wash, except it hoses down floppies.

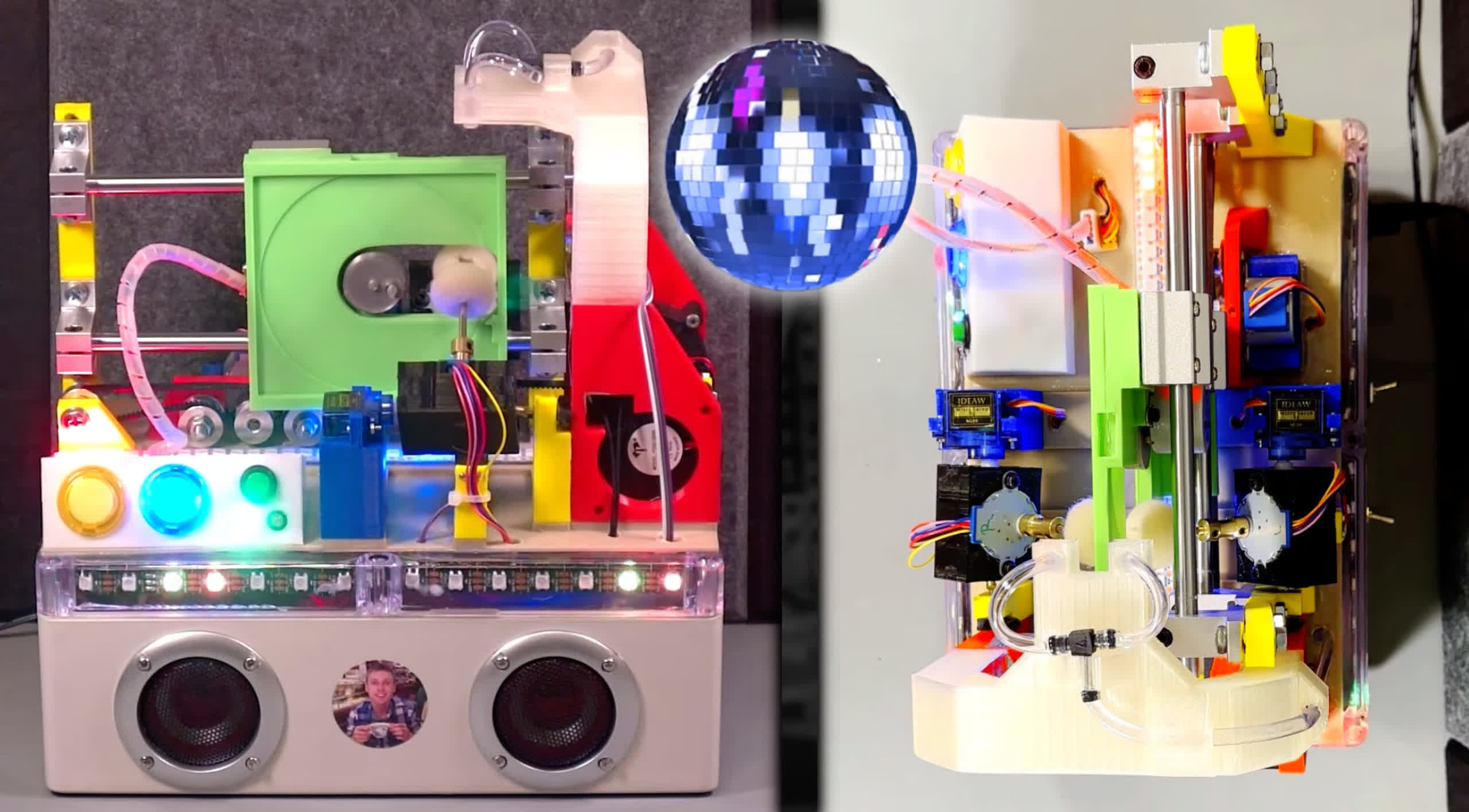

All you have to do is pop in a filthy old 3.5-inch disk and the machine does all the dirty work for you (literally). Using spinning isopropyl alcohol-coated brushes, it scrubs away all grime and buildup from the magnetic disk surface. Once cleaned, it then blasts the disk with warm air to quickly dry it off. All accompanied by flashing lights and music to keep you occupied, of course.

We say it resembles a car wash because of the way the floppy moves inside. There's also a lot of moving machinery involved, including a line of motors, pumps, and even heating elements. Motors are separate for rotating the brushes, pivoting them in and out, spinning the disk, and sliding it into position.

There's also a green button that lets you cycle between 'clean disk,' 'dry disk,' and 'clean and dry disk' modes. The machine goes as far as providing spoken feedback for these actions when you hit the button.

It's certainly much more than a glorified high school project and looks polished enough to spend money on. All of these intricate mechanisms, the music, and the lights are controlled by a couple of Arduino Mini Nano V3.0 boards.

"Due to the amount of I/O required, I ended up using two Arduinos to control it, and one Arduino was in charge of the other," notes Smith.

The machine does not fully run on its own though, as you still have to press buttons to switch between different operating modes. But it beats having to scrub those magnetic platters manually.

Smith says he designed the entire apparatus himself in TinkerCAD software and then 3D printed most of the components. He even put his creation to the test by comparing machine-cleaned disks to manually cleaned ones using both isopropyl alcohol and dish soap solutions, and the results were pretty encouraging. More importantly, the machine absolutely nailed the drying process.